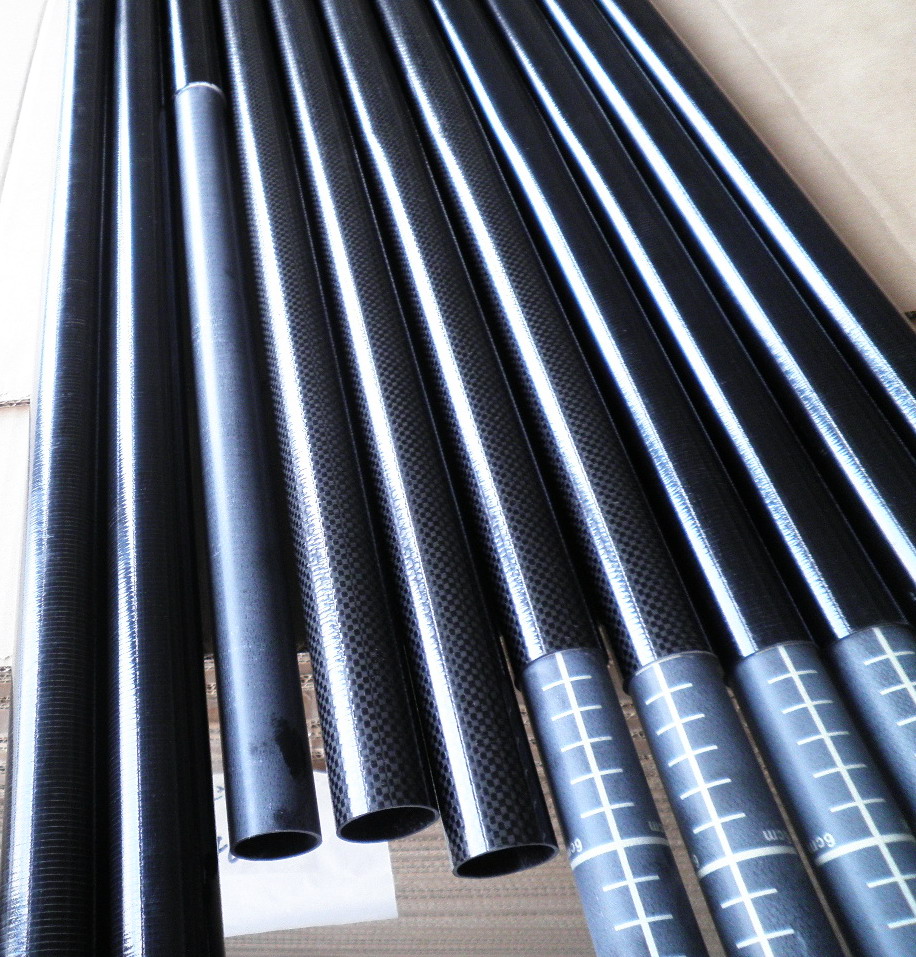

Roll-wrapped Fiberglass/ Carbon fiber Tubes and Poles

![]()

Pulwell makes various composite (fiberglass/ carbon fiber) tubes and poles using prepreg by roll-wrapping process.

Pulwell makes various composite (fiberglass/ carbon fiber) tubes and poles using prepreg by roll-wrapping process.

Prepreg is fiber such as carbon, glass or aramid fiber reinforced resins that cure under heat and pressure to form exceptionally strong yet light weight components.

The thermoset resin cures at elevated temperature,undergoing a chemical reaction that transforms the prepreg into a solid structural material that is highly durable, temperature resistant, exceptionally stiff and extremely lightweight.

Pulwell composite tubes may consist of various fiber or fabrics, including carbon fiber prepreg (graphite), Kevlar®, fiberglass (S-Glass and E-Glass), and even metallic strands or ribbons. With carbon fiber, the high strength-to-weight ratio is the real key. For engineers and product designers, the versatility of prepreg makes it ideal for creating custom light-weight tubing for many applications. Most often, our engineers maximize performance and minimize cost of custom tubes by using unidirectional carbon or glass fiber and bi-axial carbon or aramid fiber woven fabrics prepreg to meet specific customer requirements.

fiberglass (S-Glass and E-Glass), and even metallic strands or ribbons. With carbon fiber, the high strength-to-weight ratio is the real key. For engineers and product designers, the versatility of prepreg makes it ideal for creating custom light-weight tubing for many applications. Most often, our engineers maximize performance and minimize cost of custom tubes by using unidirectional carbon or glass fiber and bi-axial carbon or aramid fiber woven fabrics prepreg to meet specific customer requirements.

The roll-wrapping process provides versatility in design and repeatable quality standards.The characteristics of the tubes can be influenced by the use of different textures.We offer following grain directions:

●Unidirectional fiber orientation (in the longitudinal direction of the tube): high resistance to bending

●90° fiber orientation (in radial direction of the tube): high pressure resistance against radial stress

●± 45° fiber orientation: high torsion strength

●0°/90° fiber orientation (plain weave or structural weave): typical carbon optics

We are also able to offer different fiber angles for special use as well as a combination of different fiber angles

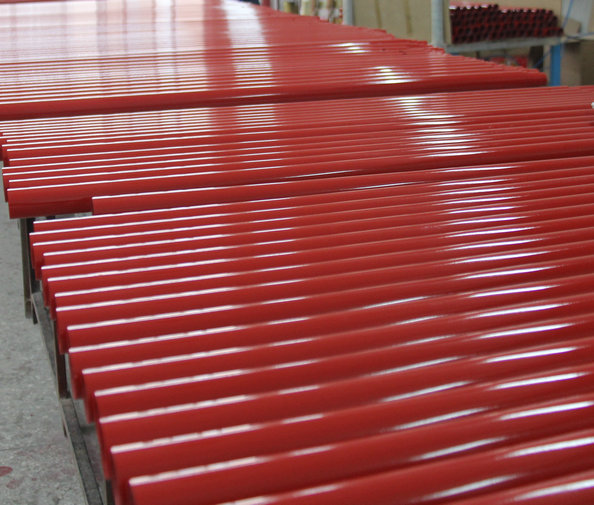

The tubes are offered in different surface qualities, raw wound, sanded, sanded & varnished (clear varnish polished, clear varnish matte or in the most RAL colors). And if your parts require painting or decorating, we have extensive capabilities in squeegee painting, spray painting, silk screening, pad printing, heat transfer decal application and even foil stamping. Drilling, cutting,assembling or gluing also are available.

The tubes are offered in different surface qualities, raw wound, sanded, sanded & varnished (clear varnish polished, clear varnish matte or in the most RAL colors). And if your parts require painting or decorating, we have extensive capabilities in squeegee painting, spray painting, silk screening, pad printing, heat transfer decal application and even foil stamping. Drilling, cutting,assembling or gluing also are available.

Pulwell produces a variety of carbon fiber, fiberglass and hybrid composite tubing products such as tent poles, bicycle tubes, tripod tubes, hockey sticks, conveyor rollers, ski poles, arrows, boom poles, kayak paddle tubes, gaff hooks, bow stabilizers, kite spars, curling brooms, and numerous other custom tube designs for various industrial and consumer applications. As you might imagine, carbon or composite tubes often replace steel tubing, aluminum tubing, plastic tubes and even fiberglass tubes with stronger, lighter and better alternatives.

custom tube designs for various industrial and consumer applications. As you might imagine, carbon or composite tubes often replace steel tubing, aluminum tubing, plastic tubes and even fiberglass tubes with stronger, lighter and better alternatives.

Applications

* Engineering (e.g. transport shafts)

* Robotic (e.g. grappler arms)

* Aeronautical Engineering

* Handling Systems

* Measurement Engineering

* Telescopic Systems

* Automotive Industry

* Medical technology (e.g. prosthetics)

* Scale Modeling / Model Making

* Consumer Electronics (e.g. pick up heads)

* Sporting Goods (e.g. paddle shafts)

* Lifestyle (e.g. cases for writing utensils)

Custom Products are available

Contact Pulwell for more information

No.20 Lianhong Road, Torch High-Tech Industrial Zone, Zhongshan City, Guangdong 528437, PRC

Copyright © 2025 Pulwell Composites Co.,Ltd. All rights Reserved

Tel:+86-760-86133399, Fax:+86-760-86133398